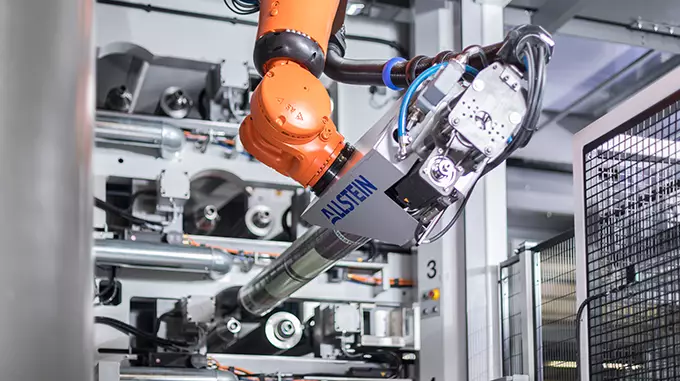

Maximize your productivity

Your printing press is most productive when it is producing. There is no doubt about that. That's why it is mandatory to eliminate machine downtime as best as possible. This is exactly what our A CHANGE technology helps you to do. A CHANGE enables you to set up the press using spare print units at full production speed: Prepare the following job while the current one is being printed. But that's not all. With our “Change on the fly”-mode, you can print continuously and switch seamlessly from the current job to the next design – And all this without having to stop production and almost without waste (we’re still working to eliminate the 2–3 meters of waste as the jobs switch). Realize your own non-stop production. With our A CHANGE technology.